The high-frequency induction (HFI) resistance pressure welding technique for longitudinal welding. The endless strip passes through rolling stands where it is shaped to an open pipe, which runs through a high-frequency inductor consisting of a metal coil with single or multiple windings. As a result, high-frequency ring current is induced into the pipe that closes preferably at the strip edges which converge in the welding point. The temperature required for welding is generated by resistance heating of a narrow zone along the strip edges.

The heated strip edges are squeezed together by pressure rollers, resulting in a homogeneous longitudinal weld without any filler metals. The flash generated on the inside and outside surfaces during welding is scraped off to the level of the pipe surface with special tools.

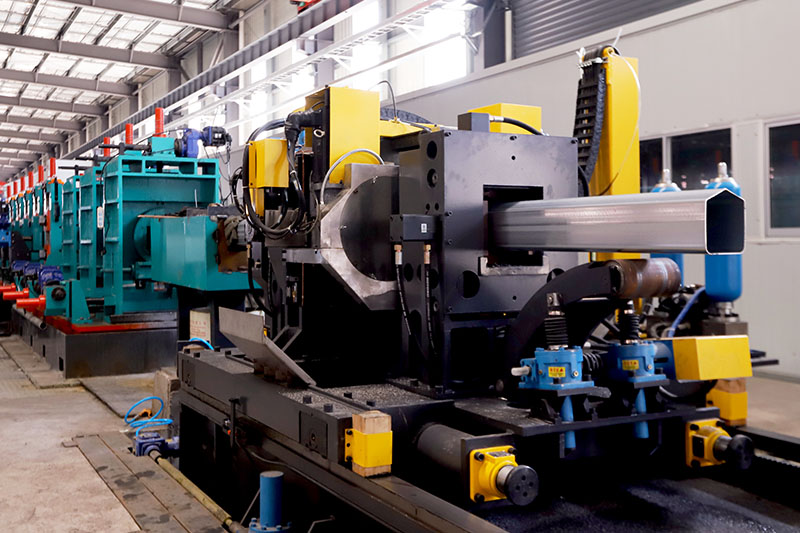

Immediately afterwards, the HFI weld is subjected to a multi-step inductive annealing treatment to ensure that the properties in the weld area match those of the base material. Then the continuous pipe string is straightened, size rolled and finally cut to length by a flying saw.

Coil edges are milled using carbide cutters in order to assure a high quality weld. Coils are then formed by cold forming method using a set of cage rolls and fin passes, and then joined using high frequency currents using induction or alternatively conduction methods.

The process begins with the cutting of the strip of the required size on slitting line and then fed through the Tube Mill for formation of line pipe. Once the formation of pipe is done, it is passed through the high frequency welder where the edges are welded together.

During the process of welding, because of immense generation of heat, there is formation of beads on both the edges, inside and outside the pipes. These beads are then cut in order to have unrestricted flow of fluid/gas inside the pipe.

Thereafter, pipes are cut into the required length and are transferred to finishing sections for further processing and testing of the line pipes like straightening, End Chamfering/Facing, Hydro-testing, Non-destructive Testing, Threading, Galvanizing etc., depending on the requirement of the customer.